Esseco adopts an environmental protection policy focused on innovation, research, and the continuous improvement of its performance. It invests in the use of the best available technologies to reduce environmental impact and promotes sustainable solutions across the entire production chain.

In the energy sector, Esseco has defined a strategy aimed at increasing independence from external supplies and fossil fuels, focusing instead on renewable sources and a responsible approach to resource use.

Esseco implements a circular economy model focused on resource recovery, production efficiency, and the reduction of environmental impacts. Our approach translates into process optimization, byproduct valorization, and plant integration, facilitating the internal reuse of energy, water, and materials.

The continuous renewal of our production activities is based on the commitment to transform every phase of the industrial cycle into an opportunity to generate value sustainably.

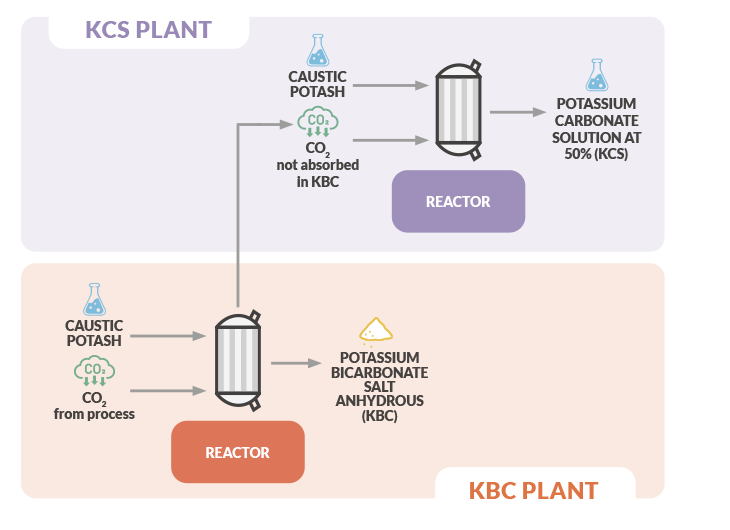

Esseco has developed a production process capable of reusing a significant portion of the CO₂ generated from sodium carbonate dissolution, combining it with caustic potash—produced with 75% renewable energy—to obtain anhydrous KHCO₃ salt. The remaining CO₂ not absorbed in this phase is used to produce 50% K₂CO₃ solution, again in combination with caustic potash derived from renewable energy.

The resulting derivatives are used in high-value sectors such as pharmaceuticals, food, and animal feed, creating a sustainable and circular production model.

Water is a fundamental resource for Esseco’s production processes, and the company is committed to its efficient and sustainable management. This has been achieved through plant design, as in the case of Sodium Dithionite/Sodium Hydrosulfite, where the patented solution enables the recycling of mother liquors, leading to significant water savings.

To reduce consumption, Esseco has implemented recovery and recycling systems in cooling circuits. Water withdrawals and discharges are monitored with certified instrumentation in compliance with environmental regulations.

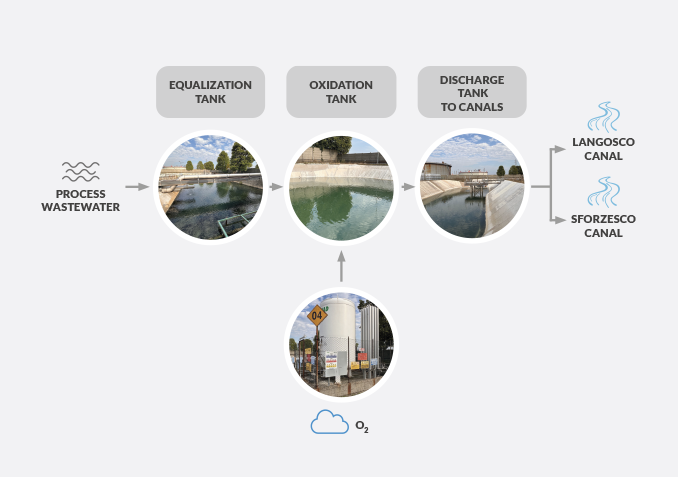

At the Trecate plant, all wastewater is directed to a physico-chemical treatment plant, where it undergoes neutralization and oxidation processes before being discharged into the Langosco or Sforzesco canals via a 2 km pipeline.

Thanks to physico-chemical treatments and a continuous monitoring system, Esseco ensures that all industrial process water is safe for the environment and compliant with regulations before release.

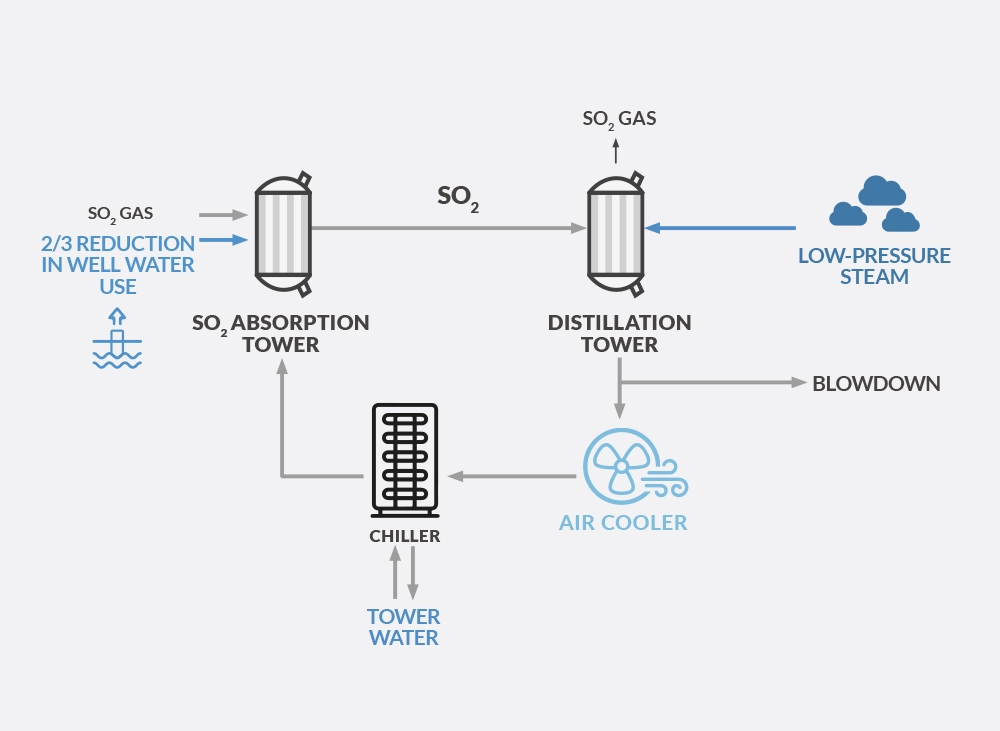

Among ongoing projects, SOG/SL includes the installation of a chiller unit paired with a pre-cooling air cooler, which will reduce groundwater extraction from a deep well.

This strategic measure addresses water scarcity challenges in the context of climate change. The system will use mechanically cooled water instead of groundwater, promoting more sustainable management from both an environmental and economic perspective.

To help mitigate climate change, Esseco carefully monitors emissions from its plants to ensure compliance with regulatory limits.

The San Martino di Trecate (NO) plant is authorized under AIA (Integrated Environmental Authorization) by the Ministry.